In industrial and commercial applications, gear pumps have emerged as a cornerstone for transferring fluids efficiently and reliably. From lubricating machinery to moving high-viscosity liquids, these pumps are highly valued for their simplicity, durability, and adaptability. Understanding the mechanics and applications of gear pumps can help industries optimize their fluid-handling operations.

What Are Gear Pumps?

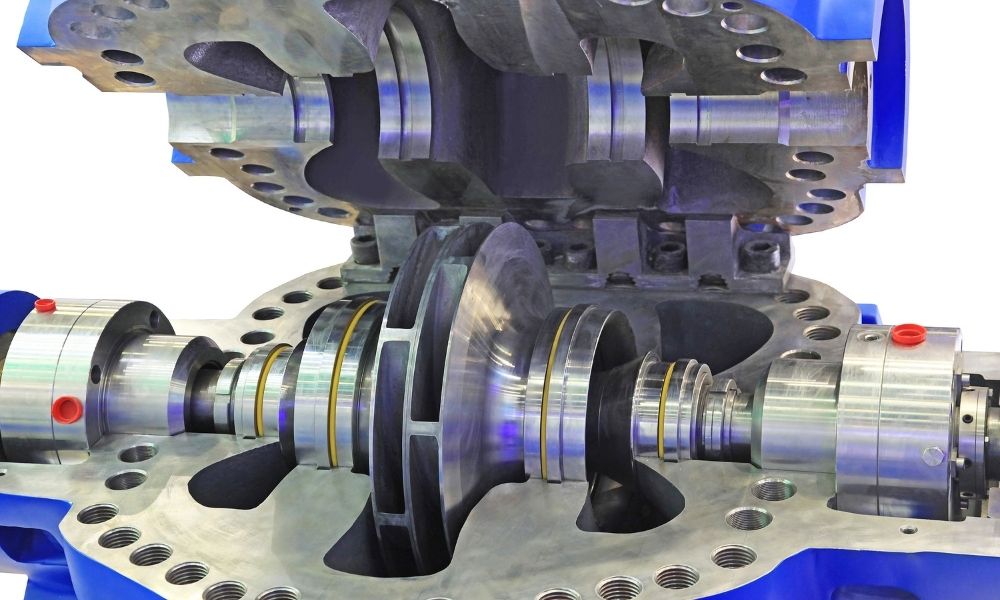

Gear pumps are positive displacement pumps that use meshing gears to transfer fluids. They operate by trapping liquid between the teeth of rotating gears and pushing it through the pump housing. The process is straightforward yet incredibly effective, making gear pumps a popular choice in various industries. Their ability to handle thick, viscous fluids and maintain consistent flow rates sets them apart from other types of pumps.

How Gear Pumps Work

At the core of a gear pump’s operation are two interlocking gears—typically a driving gear and a driven gear—that rotate within a tightly sealed chamber. As the gears turn, they create a vacuum that draws fluid into the pump. The fluid is then carried between the gear teeth and the pump housing until it is expelled through the discharge port. This continuous action ensures a steady and controlled flow of liquid.

Applications of Gear Pumps

Gear pumps are incredibly versatile and find applications in numerous industries:

- Manufacturing: Used to transport oils, chemicals, and adhesives in production processes.

- Food and Beverage: Ideal for moving syrups, chocolate, and other high-viscosity liquids.

- Automotive: Frequently used as lube oil pumps to ensure the smooth operation of engines and machinery.

- Pharmaceuticals: Essential for handling sensitive and sterile liquids.

- Petrochemical: Effective in transferring fuels, lubricants, and other petroleum products.

Advantages of Gear Pumps

Gear pumps offer a range of benefits that make them indispensable in industrial operations:

- Consistency: Deliver a uniform flow rate, regardless of pressure fluctuations.

- Durability: Built to withstand harsh conditions and prolonged use.

- Versatility: Capable of handling a wide range of fluids, including highly viscous materials.

- Low Maintenance: Simple design reduces the likelihood of breakdowns and simplifies repairs.

The Role of Lube Oil Pumps

Among the various applications of gear pumps, their use as lube oil pumps is particularly noteworthy. These pumps are crucial for maintaining the lubrication systems in engines, turbines, and industrial machinery. By ensuring a steady supply of lubricant, lube oil pumps minimize friction and wear, extending the life of critical components and reducing maintenance costs.

Selecting the Right Gear Pump

When choosing a gear pump, it’s important to consider factors such as:

- Fluid Type: Compatibility with the fluid’s viscosity and chemical properties.

- Flow Rate: Ensuring the pump meets the required delivery volume.

- Pressure Requirements: Matching the pump’s capacity to the system’s pressure needs.

- Material Construction: Selecting durable materials that can withstand the operating environment.

Challenges and Solutions

While gear pumps are highly efficient, they may encounter challenges such as wear and tear from abrasive fluids or reduced efficiency with extremely low-viscosity liquids. Regular maintenance, selecting the appropriate materials, and using filters can mitigate these issues and ensure optimal performance.

Future Innovations in Gear Pumps

Advancements in materials and design are driving the evolution of gear pumps. Innovations such as self-lubricating gears, enhanced sealing technologies, and smart monitoring systems are making gear pumps more reliable and efficient. These developments promise to expand the applications of gear pumps and solidify their position as a go-to solution for fluid handling.

Gear pumps play a vital role in numerous industries, offering unmatched efficiency and reliability. Whether used as lube oil pumps in automotive applications or for moving high-viscosity fluids in manufacturing, their versatility is unparalleled. By understanding their mechanics and applications, businesses can make informed decisions and harness the full potential of gear pumps to optimize their operations.